- Empty cart.

- Continue Shopping

Free Delivery & Shipping

For all order over $200.

Return Warranty

If you’re not satisfied.

24/7 Technical Support

Anytime & anywhere you’re.

Member Gifts

Discount coupons weekends.

Our Daily Choices

Shirt cotton-voile

Today Flash Sales

Shirt cotton-voile

Fit Jeans L’Homme Washed Slim

Track pants lim-fit technical

Top Selling Products

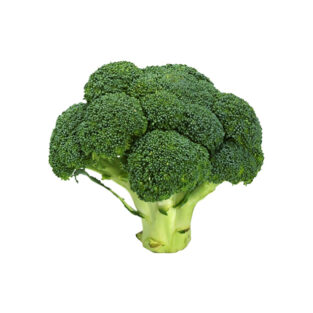

Why Choose Money Plant Organics?

At Money Plant Organics, we take pride in delivering 100% pure, high-quality products are packed straight from the source/mills/farming land. Our commitment to excellence ensures that every spice, dry fruit, and cold-pressed oil is fresh, unadulterated, and packed with natural goodness.

✅ Premium Quality – Handpicked and carefully processed for purity.

✅ No Additives or Preservatives – Just natural, wholesome ingredients.

✅ Rich in Nutrients & Flavor – Enhance your health and elevate your meals.

✅ Ethically Sourced – Supporting sustainable and responsible sourcing.

Choose Money Plant Organics – Authentic, Pure, Trusted. 🌿

Money Plant Organics – Certified for Purity & Quality

At Money Plant Organics, we take pride in delivering only the finest quality products. Our certifications reflect our commitment to purity, safety, and sustainability. From organic and pesticide-free lab testing to FSSAI and ISO 9001:2015 standards, each certification ensures that our edible oils, spices, and dry fruits meet the highest industry benchmarks. Trust us for products that are natural, authentic, and responsibly sourced! 🌿✅